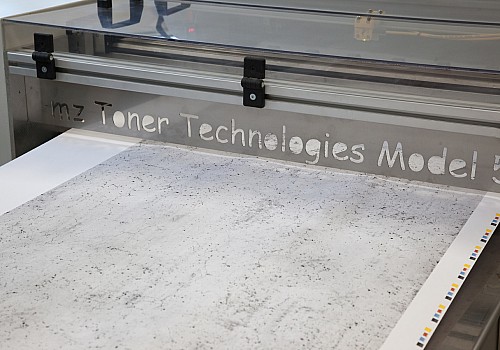

Ceramic digital print from our factory is the result of investment over many years. The laser print machine to produce ceramic templates in large format is 100% one of our own developments. Thereby processed are the, also self developed toners from mz Toner Technologies GmbH & Co.KG.

The advantages against direct print machines with inkjets are often decision in our area of application:

Laser printers print more quicker and the motifs are disbanded at a higher level.

Applications

The motifs created in ceramic digital print are burnt into the carrying material of glass ceramic or concrete and can already be manufactured from issue 1. Here also the inorganic colour pigments combine with the substrates. On grounds of the fine resolution of the ceramic toner prints, the architectural materials enhanced with this are suitable for inside and outside.

The ceramic digital laser print distinguishes itself from the competition in the following criteria:

Issue volume of the printer: 250 square metres per hour.

Colour brilliance: with our connected toner production we create real ceramic red. And also the otherwise difficult green tones we can – if desired – in single tone development manufacture that for our clients and contractors. Especially in architecture tolerances against the draft are often not permitted.

Large areas: Glass sheets, facades, signs, complete glass structures – never mind which area is concerned, with the measurements: 90 cm x endless we get them recorded. Wider areas than this format we realise with suitable decor or batches.

Resolution: our ceramic digital print dissolves images and motifs at up to 600 dpi and is thus suitable for interior design. Even when looking at glass or ceramic motifs from up close they still cause a strong affect.